| COLD HEADING | ||

|---|---|---|

| x | ||

Heading is a metalworking process that incorporates forging, extruding and upsetting processes.

It is often performed in the cold state, resulting in coldworking. This process can either produce nearly completed parts that require secondary operations or quite often produce finished products, as with screws and bolts.

An important consideration in heading is the tendency for the wire to buckle if its unsupported length to diameter ratio is too high. This ratio usually is limited to less than 3:1 but with appropriate dies, it can be higher.

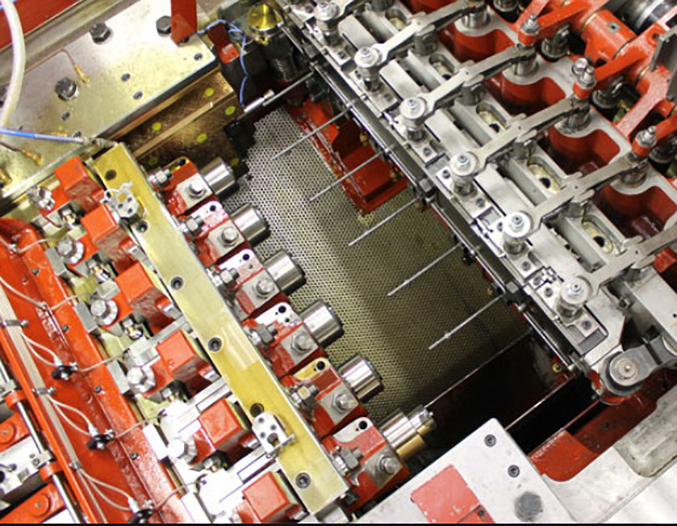

There are a variety of cold heading machines but typically for fastener and bolt manufacturing you will see One Die Two Blow, up to Five Die Six Blow and beyond. Multi-Die headers allow for more complex parts to be formed as part of one process due to the above limitations of diameter ratio reductions.

Some advantages of cold heading a part over using a CNC lathe or using a screw machine include reduced part cost both through production speed (60-400 parts per minute) and the minimal scrap generated from a cold headed part. Also, because the part is formed rather than cut, the grain flow stays intact and creates a much stronger part for its size.

|

||